Products Name: Screw Type Water-cooled Chiller (AMC-WS Series)

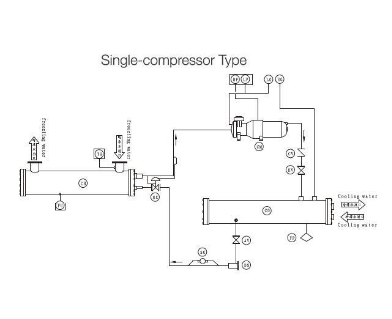

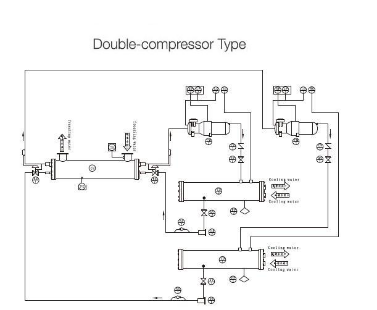

AMC-S Series screw type central Chillers adopt German-made BITZER with half-closed and twin screw compressors, models with one or two compressors, suitable for using R22 and R407C refrigerants; equipped with high efficiency tube-in-shell type condenser and evaporator ensure stable heat exchange and convenient maintenance; advanced controller with built in microprocessor which has a powerful and excellent performance.

AMC-S centralized Water-cooling System are main composed of compressor, condenser, evaporator and expansion valve. It is adopted single-stage vapor compression refrigeration system, by the principle of inter-conversion between gaseous and liquid refrigerator, to absorb and release heat. So that, achieving the results of refrigeration.

Features Specifications:

> Half-closed, double screws compressor are made in Germany with long service life.

> Stopless compressor output capacity adjusting function are designed to save power.

> Evaporator and condenser built strictly according to national standards.

> Extendibility of the controller makes upgrade of both hardware and software much easier.

> "Watchdog" technology makes microprocessor able to automatically diagnose and solve the problems.

> 512 K memory for programs and 128 K off-power data storage.

> Special touch screen panel, long service life more than 10 years.

> Function of fault query and fault statistics, convenient to analysis the fault and make improvement.

> Able to monitor the setting of actual temp and display temp trend in hours or daily.

> Support multi-language.

Single compressor specifications:

Model | AMC-40WS | AMC-50WS | RCMC-60W | AMC-70WS | AMC-80WS | AMC-90WS | ||

Power resource | - | 3Ø-380V-50HZ | ||||||

Chilling capacity | kcal/h | 113500 | 141900 | 166000 | 191800 | 220200 | 272600 | |

kw | 132 | 165 | 193 | 223 | 256 | 317 | ||

Consumption | kw | 31 | 38 | 43 | 51 | 58 | 76 | |

Operation current | A | 54 | 66 | 75 | 87 | 96 | 123 | |

Startup current | A | 218D/411D D | 269D/508D D | 290D/485D D | 350D/585D D | 350D/585D D | 520D//801D D | |

Capacity control | % | 100-75-50-25-0 | ||||||

Compressor | Type | - | Half-closed and double-screw type | |||||

Quantity | - | 1 | ||||||

Startup type | - | Divided winding starting | ||||||

Oil heater | W | 200 | 300 | |||||

Chilled oil | Type | - | B320SH | |||||

Filling quantity | L | 9 | 15 | 22 | ||||

Refrigerant | Type | - | R-22 | |||||

Filling quantity | KG | 21 | 26 | 30 | 35 | 40 | 50 | |

Throttling | - | Thermostatic expansion valve | ||||||

Evaporator | Type | - | Tube-in-shell high efficient heat exchanger | |||||

Chiller water flow | m³/h | 23 | 28 | 33 | 38 | 44 | 55 | |

Pressure expense | KPa | 54 | 54 | 54 | 57 | 57 | 57 | |

Water pipe joint | PT | 3" | 3" | 3" | 4" | 4" | 4" | |

Condenser | Type | - | Tube-in-shell high efficient heat exchanger | |||||

Chilling water flow | m³/h | 30 | 37 | 43 | 50 | 57 | 71 | |

Pressure expense | KPa | 54 | 54 | 57 | 57 | 59 | 59 | |

Water pipe joint | PT | 2-1/2" | 3" | 3" | 3" | 3" | 4" | |

Protection device | - | High pressure switch, low pressure switch, Anti-freezing switch, fusible plug, compressor over-heat protection, motor over-heat protection, exhaust air over-heat protection, pump over-load protection, oil over-heat protection, phase reverse protection, voltage insecure, cooling water over-heat protection, chilled water flow protection, cooling water flow shortage protection, cooling tower over current protection, and so on. | ||||||

External dimensions | L | mm | 2175 | 2195 | 2245 | 2860 | 2860 | 2975 |

W | mm | 935 | 935 | 935 | 1015 | 1015 | 1015 | |

H | mm | 1430 | 1500 | 1655 | 1710 | 1710 | 1965 | |

A | mm | 1100 | 1100 | 1100 | 1200 | 1200 | 1300 | |

B | mm | 690 | 690 | 690 | 790 | 790 | 790 | |

C | mm | 690 | 760 | 820 | 860 | 860 | 1000 | |

D | mm | 170 | 190 | 240 | 240 | 240 | 270 | |

E | mm | 100 | 100 | 120 | 120 | 120 | 160 | |

F | mm | 75 | 80 | 80 | 125 | 105 | 100 | |

G | mm | 240 | 240 | 230 | 475 | 475 | 400 | |

I | mm | 75 | 156 | 170 | 200 | 200 | 315 | |

Net weight | Kg | 1020 | 1060 | 1270 | 1370 | 1400 | 1870 | |

Operating weight | Kg | 1120 | 1180 | 1420 | 1550 | 1580 | 2100 | |

Noise | dB(A) | 74 | 76 | 78 | ||||

Model | AMC-110WS | AMC-120WS | AMC-150WS | AMC-180WS | AMC-200WS | ||

Power resource | - | 3Ø-380V-50HZ | |||||

Chilling capacity | kcal/h | 312200 | 360300 | 470400 | 541800 | 621800 | |

kw | 363 | 419 | 547 | 630 | 723 | ||

Consumption | kw | 80 | 90 | 121 | 136 | 156 | |

Operation current | A | 136 | 151 | 199 | 221 | 246 | |

Startup current | A | 612D/943D D | 665D/1023D D | 465Y/1442D | 586Y/1853D | 650Y/2029D | |

Capacity control | % | 100-75-50-25-0 | |||||

Compressor | Type | - | Half-closed and double-screw type | ||||

Quantity | - | 1 | |||||

Startup type | - | Divided winding starting | Y-Δ | ||||

Oil heater | W | 300 | |||||

Chilled oil | Type | - | B320SH | ||||

Filling quantity | L | 22 | 28 | ||||

Refrigerant | Type | - | R-22 | ||||

Filling quantity | KG | 57 | 66 | 86 | 99 | 113 | |

Throttling | - | Thermostatic expansion valve | |||||

Evaporator | Type | - | Tube-in-shell high efficient heat exchanger | ||||

Chiller water flow | m³/h | 62 | 72 | 94 | 109 | 125 | |

Pressure expense | KPa | 59 | 59 | 62 | 62 | 67 | |

Waterpipe joint | PT | 4" | 4" | 5" | 6" | 6" | |

Condenser | Type | - | Tube-in-shell high efficient heat exchanger | ||||

Chilling water flow | m³/h | 81 | 94 | 122 | 141 | 162 | |

Pressure expense | KPa | 62 | 62 | 65 | 67 | 67 | |

Water pipe joint | PT | 4" | 4" | 5" | 5" | 5" | |

Protection device | - | High pressure switch, low pressure switch, Anti-freezing switch, fusible plug, compressor over-heat protection, motor over-heat protection, exhaust air over-heat protection, pump over-load protection, oil over-heat protection, phase reverse protection, voltage insecure, cooling water over-heat protection, chilled water flow protection, cooling water flow shortage protection, cooling tower over current protection, and so on. | |||||

External dimensions | L | mm | 2985 | 3010 | 3510 | 3590 | 3595 |

W | mm | 1025 | 1055 | 1105 | 1150 | 1175 | |

H | mm | 1975 | 1990 | 2140 | 2155 | 2195 | |

A | mm | 1300 | 1300 | 1600 | 1600 | 1600 | |

B | mm | 790 | 790 | 9000 | 900 | 980 | |

C | mm | 1010 | 1010 | 1120 | 1120 | 1160 | |

D | mm | 270 | 245 | 275 | 240 | 240 | |

E | mm | 160 | 175 | 175 | 240 | 240 | |

F | mm | 100 | 100 | 125 | 130 | 175 | |

G | mm | 405 | 405 | 550 | 540 | 540 | |

I | mm | 310 | 245 | 250 | 340 | 340 | |

Net weight | Kg | 1870 | 2070 | 2790 | 2910 | 3240 | |

Operating weight | Kg | 2220 | 2340 | 3120 | 3240 | 3760 | |

Noise | dB(A) | 80 | 82 | ||||

Remark:

1) Condition for parameter test: temperature of chilled water: inlet 12°C,outlet 7°C;temperature of chilling water: Inlet 30°C, outlet 35°C.

2) Noise test: 1m away from the due front of the machine, 1.5m high away from the machine(noise: below 30dB)

3) Any special requirements, have to be advised before order.

Please excuse for not note if some specifications of products are changed.

Double compressor specifications:

Model | AMC-40WS-D | AMC-50WS-D | AMC-60WS-D | AMC-70WS-D | AMC-80WS-D | AMC-90WS-D | ||

Power resource | - | 3Ø-380V-50HZ | ||||||

Chilling capacity | kcal/h | 226200 | 283800 | 331100 | 383600 | 440300 | 547800 | |

kw | 263 | 330 | 385 | 446 | 512 | 637 | ||

Consumption | kw | 62 | 76 | 87 | 102 | 115 | 136 | |

Operation current | A | 108 | 132 | 149 | 175 | 190 | 232 | |

Startup current | A | 218D/411D D | 269D/508D D | 290D/485D D | 350D/585D D | 423D/686D D | 520D//801D D | |

Capacity control | % | 100-75-50-25-0 | ||||||

Compressor | Type | - | Half-closed and double-screw type | |||||

Quantity | - | 2 | ||||||

Startup type | - | Divided winding starting | ||||||

Oil heater | W | 200x2 | 300x2 | |||||

Chilled oil | Type | - | B320SH | |||||

Filling quantity | L | 9x2 | 15x2 | 22x2 | ||||

Refrigerant | Type | - | R-22 | |||||

Filling quantity | KG | 21x2 | 26x2 | 30x2 | 35x2 | 39x2 | 46x2 | |

Throttling | - | Thermostatic expansion valve | ||||||

Evaporator | Type | - | Tube-in-shell high efficient heat exchanger | |||||

Chiller water flow | m³/h | 45 | 57 | 66 | 77 | 88 | 110 | |

Pressure expense | KPa | 57 | 57 | 59 | 62 | 62 | 62 | |

Water pipe joint | PT | 4" | 4" | 4" | 5" | 5" | 5" | |

Condenser | Type | - | Tube-in-shell high efficient heat exchanger | |||||

Chilling water flow | m³/h | 59 | 74 | 86 | 100 | 115 | 142 | |

Pressure expense | KPa | 51 | 54 | 59 | 59 | 59 | 62 | |

Water pipe joint | PT | 2-1/2"x2 | 3" | 3"x2 | 3"x2 | 3"x2 | 4"x2 | |

Protection device | - | High pressure switch, low pressure switch, Anti-freezing switch, fusible plug, compressor over-heat protection, motor over-heat protection, exhaust air over-heat protection, pump over-load protection, oil over-heat protection, phase reverse protection, voltage insecure, cooling water over-heat protection, chilled water flow protection, cooling water flow shortage protection, cooling tower over current protection, and so on. | ||||||

External dimensions | L | mm | 2850 | 2850 | 3040 | 3130 | 3140 | 3760 |

W | mm | 1150 | 1150 | 1250 | 1250 | 1250 | 1400 | |

H | mm | 1450 | 1450 | 1760 | 1790 | 1810 | 2030 | |

A | mm | 1300 | 1300 | 1300 | 1600 | 1600 | 1600 | |

B | mm | 1040 | 1040 | 1140 | 1140 | 1140 | 1290 | |

C | mm | 770 | 770 | 955 | 970 | 975 | 1085 | |

D | mm | 215 | 215 | 275 | 270 | 270 | 265 | |

E | mm | 100 | 100 | 120 | 120 | 120 | 175 | |

F | mm | 230 | 230 | 275 | 300 | 275 | 375 | |

G | mm | 410 | 410 | 400 | 245 | 400 | 545 | |

I | mm | 70 | 70 | 245 | 250 | 245 | 250 | |

Net weight | Kg | 1790 | 1790 | 2340 | 2420 | 2500 | 3580 | |

Operating weight | Kg | 1920 | 1970 | 2520 | 2620 | 2710 | 3920 | |

Noise | dB(A) | 72 | 76 | 80 | ||||

Model | AMC-110WS-D | AMC-120WS-D | AMC-150WS-D | AMC-180WS-D | AMC-200WS-D | ||

Power resource | - | 3Ø-380V-50HZ | |||||

Chilling capacity | kcal/h | 623500 | 721500 | 940000 | 1083600 | 1243600 | |

kw | 725 | 839 | 1093 | 1260 | 1446 | ||

Consumption | kw | 160 | 180 | 230 | 272 | 305 | |

Operation current | A | 273 | 305 | 373 | 452 | 503 | |

Startup current | A | 612D/943D D | 665D/1023D D | 465Y/1442D | 586Y/1853D | 650Y/2029D | |

Capacity control | % | 100-75-50-25-0 | |||||

Compressor | Type | - | Half-closed and double-screw type | ||||

Quantity | - | 2 | |||||

Startup type | - | Y-Δ | |||||

Oil heater | W | 300x2 | |||||

Chilled oil | Type | - | B320SH | ||||

Filling quantity | L | 22x2 | 28x2 | ||||

Refrigerant | Type | - | R-22 | ||||

Filling quantity | KG | 54x2 | 61x2 | 78x2 | 92x2 | 104x2 | |

Throttling | - | Thermostatic expansion valve | |||||

Evaporator | Type | - | Tube-in-shell high efficient heat exchanger | ||||

Chiller water flow | m³/h | 125 | 144 | 188 | 217 | 249 | |

Pressure expense | KPa | 65 | 65 | 67 | 67 | 69 | |

Water pipe joint | PT | 6" | 6" | 6" | 8" | 8" | |

Condenser | Type | - | Tube-in-shell high efficient heat exchanger | ||||

Chilling water flow | m³/h | 162 | 188 | 244 | 282 | 323 | |

Pressure expense | KPa | 62 | 62 | 65 | 67 | 67 | |

Water pipe joint | PT | 4"x2 | 4"x2 | 5"x2 | 5"x2 | 5"x2 | |

Protection device | - | High pressure switch, low pressure switch, Anti-freezing switch, fusible plug, compressor over-heat protection, motor over-heat protection, exhaust air over-heat protection, pump over-load protection, oil over-heat protection, phase reverse protection, voltage insecure, cooling water over-heat protection, chilled water flow protection, cooling water flow shortage protection, cooling tower over current protection, and so on. | |||||

External dimensions | L | mm | 3760 | 3760 | 4100 | 4100 | 4250 |

W | mm | 1400 | 1400 | 1600 | 1750 | 1750 | |

H | mm | 2040 | 2080 | 2260 | 2290 | 2360 | |

A | mm | 1600 | 1600 | 1600 | 1600 | 1600 | |

B | mm | 1290 | 1290 | 1480 | 1630 | 1630 | |

C | mm | 1130 | 1135 | 1240 | 1270 | 1305 | |

D | mm | 265 | 265 | 290 | 290 | 290 | |

E | mm | 175 | 175 | 240 | 240 | 250 | |

F | mm | 375 | 375 | 450 | 450 | 430 | |

G | mm | 545 | 545 | 500 | 500 | 775 | |

I | mm | 250 | 250 | 100 | 100 | 90 | |

Net weight | Kg | 3750 | 3880 | 5050 | 5340 | 5600 | |

Operating weight | Kg | 4110 | 4250 | 5490 | 5830 | 6260 | |

Noise | dB(A) | 80 | 82 | ||||

Remark:

1) Condition for parameter test: temperature of chilled water: inlet 12°C,outlet 7°C;temperature of chilling water: Inlet 30°C, outlet 35°C.

2) Noise test: 1m away from the due front of the machine, 1.5m high away from the machine (noise: below 30dB)

3) "-D" means double compressor.

4) Any special requirements have to be advised before order.

Please excuse for not note if some specifications of products are changed.

|  |

Copyright © 2016 Aumax Industrial (HK) Limited. All Rights Reserved Link: Plastic Crusher Plastic Granulator Plastic Shredder